Waupaca Foundry Iron Castings For Agriculture & Construction

Off-Highway Manufacturers Trust Waupaca Foundry

Minimize Off-Highway Supply Chain Risk with Quality Iron Castings

The off-highway equipment industry has relied on Waupaca Foundry for high-quality, cost-effective iron castings for more than 65 years. Back then, Pioneer Foundry and H.H. Suhs merged to form what was formerly Suhs-Rosche, which manufactured the Waupaca Chilled Plow, sleigh shoes, sash weights for windows, and the crusher jaws for use by the City of Waupaca at its stone crushing plant. In the decades since, we’ve continued to build a legacy as the most trusted supplier of gray iron and ductile iron casting solutions for agriculture, construction, diesel engine, fluid power and other off-highway parts.

Leading off-highway equipment manufacturers trust Waupaca Foundry because of our track record of stability and success. We promise to deliver the best possible cost, highest quality and reliability—and we back it all up with world-class customer service.

Waupaca Foundry’s five locations across the U.S. produce material grades including gray iron, ductile iron, high-strength ductile iron and austempered ductile iron castings.

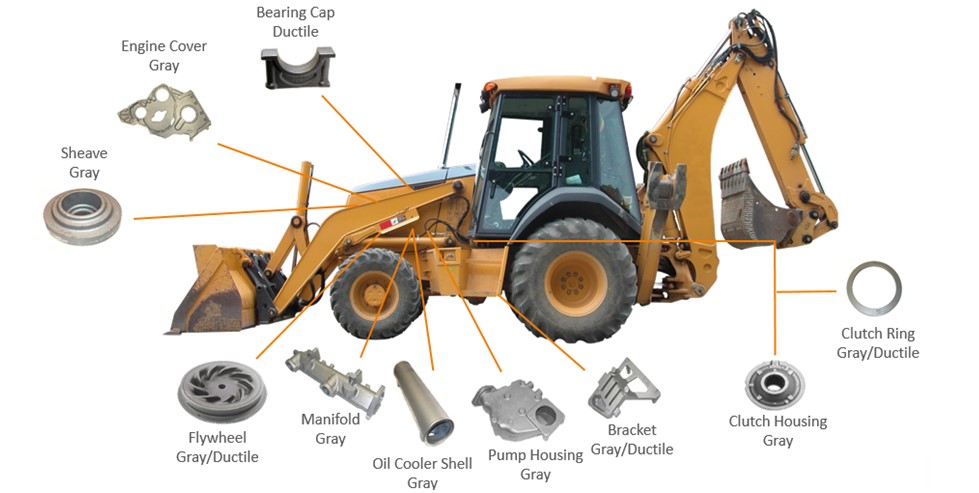

Our iron castings are used to manufacture farming and agricultural equipment including tractors, turf care equipment, implement, diesel engines and more. It’s used in the toughest construction equipment in the world to manufacture housings, flywheels weights, mounts and other components that need to withstand heavy use and unforgiving conditions.

We know that in today’s manufacturing environment, your job includes finding the best possible cost while ensuring performance and supplier stability, without sacrificing quality and delivery. Waupaca Foundry is committed to meeting manufacturer’s VA/VE, lightweighting, or cost and quality targets to enhance your bottom line.

Design collaboration ensures your off-highway equipment component is a good fit for the iron casting manufacturing process. Simulation tools identify potential issues prior to production, saving you time and money. At Waupaca Foundry, we drive the opportunity for failure out of the design process. And, Our highly attentive customer support team includes quality technicians who regularly visit customers—in person—to respond to needs and strengthen relationships. We’ve got your back.

Waupaca Foundry also offers end-to-end value added services to meet your program needs and control costs. Our capacity to produce iron castings extends to machining, heat treat, paint, and assembly, which means we manage your iron casting supply from design to your assembly line.