Additive Manufacturing Case Studies

Solve Complex Challenges with 3D Printing

Waupaca Foundry Additive Manufacturing Solves Problems, Mitigates Risk

3D printed core prototypes are cost-effective, faster and more adaptable

Additive manufacturing, or 3D printing, uses layers of material to create a part based on a digital design. 3D printed core and mold technology offers multiple benefits in the development and production of iron castings: faster launch of parts, reduced cost and improved quality.

Waupaca Foundry uses additive manufacturing to:

- Aid in iron casting design development and program launch

- Test and verify part performance prior to production

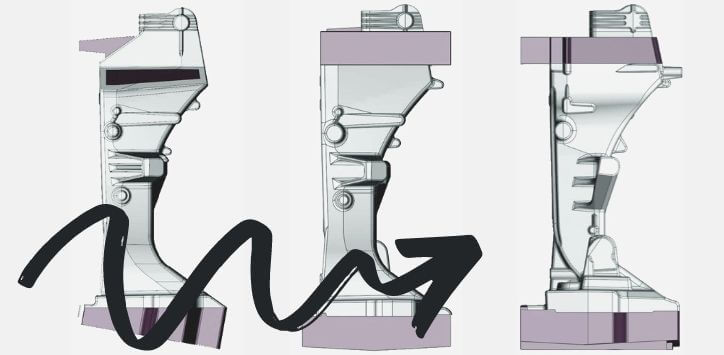

- Improve dimensional control for iron castings with complex geometry

- Replace the need for core box tooling on low-volume production parts

3D printing helps Waupaca Foundry deliver more value. Collaborative engineering, 3D printing and use of iron and sand flow simulation software offers the flexibility to test iron casting designs faster, allows for multiple iterations of geometry, and mitigates risk—all before investing in hard tooling costs.

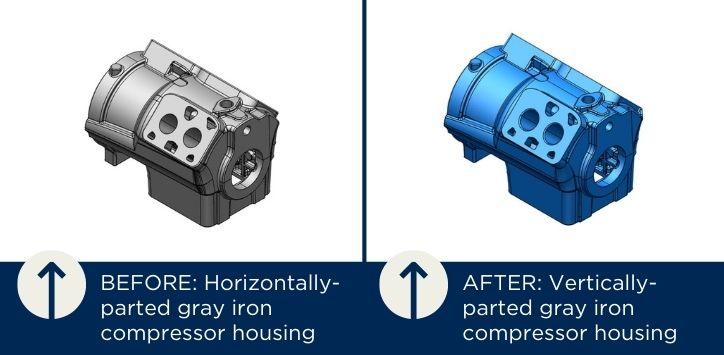

Waupaca Foundry has successfully used 3D printing to solve OEM customer quality issues and downtime, while eliminating supply chain instability in iron casting manufacturing.

Click on the case studies below to discover how Waupaca Foundry has used additive manufacturing technology to solve common challenges OEMs and their Tier 1 suppliers face. Benefits of 3D printed prototypes have included reduced costs, faster turnaround times, reshoring manufacturing and mitigating supply chain risk.

.jpg?lang=en-US&ext=.jpg)

.jpg?lang=en-US&ext=.jpg)