VA/VE Case Studies

Reduce Cost and Improved Products with Waupaca Foundry

Waupaca Foundry’s VA/VE Process Cuts Waste, Increases Efficiency

VA/VE support helps buyers reduce costs, improve function

Value Analysis (VA) and Value Engineering (VE) processes focus on collaborating to streamline manufacturing and eliminate waste from the iron casting supply chain.

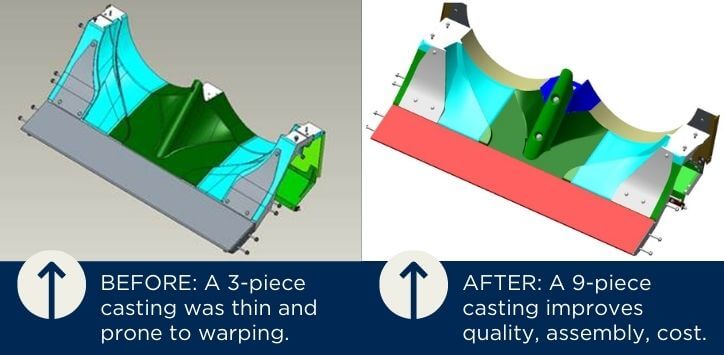

When faced with tough value management challenges from OEMs and Tier 1 suppliers, Waupaca Foundry delivers. The foundry’s teamwork-based approach to VA/VE support involves evaluating a cast iron component—raw or machined—across multiple areas, including function, cost, design and ease of manufacturing. 3-D laser scans, digital imaging and 3-D computer modeling, such as MAGMA® iron flow and Arena-flow® sand flow simulations, ensure iron castings are high quality and consistently made to specification, time after time. VA/VE can be combined with complementary techniques aimed at optimizing the manufacturing process.

Click on the case studies below to discover how Waupaca Foundry has helped OEMs and their Tier 1 suppliers increase efficiency, remove waste and cut costs through VA/VE support.