Waupaca Foundry Meets Lightweighting Targets, Cuts Cost

Iron Castings Are Lighter, Stronger, And More Cost-Effective

Reducing component weight has multiple benefits, but choosing the best lightweighting strategy requires the right partner. Waupaca Foundry offers manufacturers the clear advantage, whether their motivation is to cut material costs, meet CAFE standards or improve strength and assembly ergonomics.

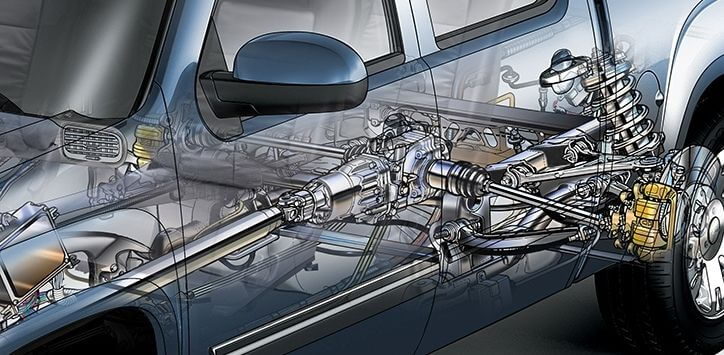

Waupaca Foundry ductile iron and HNM™ Series high-strength ductile iron solutions offer advantages compared to alternative material solutions. Cast and machined iron casting components are less expensive, stronger and smaller than aluminum parts, yet support thin wall structures and meet complex shapes. A single ductile iron casting for example can replace several weldment parts to simplify assembly and reduce manufacturing costs. Waupaca Foundry design and tooling engineers collaborate on iron casting designs for durable, cost-conscious parts that achieve even the most aggressive lightweighting and mass targets.

Lightweighting isn’t just for the automotive industry. Commercial vehicle, off-highway and oil & gas manufacturers trust Waupaca Foundry for weight and mass reduction solutions too.

Click on the case studies below to discover how Waupaca Foundry has helped OEMs and their Tier 1 suppliers reduce weight and metal component costs while improving component performance, simplifying assembly and more.