Case Study

Conversion to Ductile Iron Improves Durability and Eliminates Warranty Claims

To improve durability and wear of components assembled on commercial zero-turn mowers, Waupaca Foundry collaborated with both the machining supplier and the OEM. In short, multi-piece steel weldments were converted to single ductile iron castings, securing the performance it was unable to achieve with welded components.

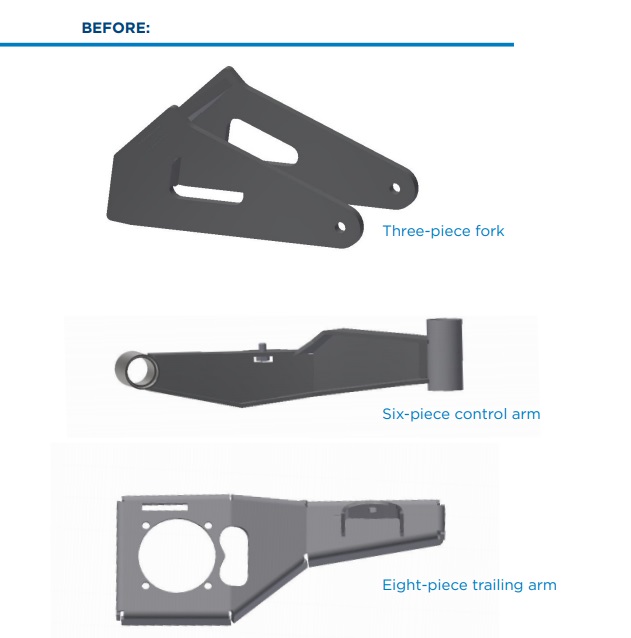

The original design of the zero-turn commercial lawn mowers planned for steel weldments in its front and rear suspensions. The design extended throughout several commercial mower models. Among them, an eight-piece rear trailing arm, a six-piece front control arm and a three-piece front fork, all of which failed impact testing.

Field tests showed that the welded trailing arm bent and twisted under impact and bearing races warped, thus presenting durability and warranty concerns. Additionally, fit is never perfect with a weldment. There are always gaps.

Prior to production on the commercial mowers, Waupaca Foundry vetted the redesigned components with iron casting models. This proactive measure confirmed that design weaknesses with the weldments could be reduced and/or eliminated with ductile iron castings. The benefit of using iron castings compared to weldments was immediately recognized and tooling was approved. In the end, multi-piece weldments were converted to one-piece ductile iron castings:

- Front fork converted from a three-piece weldment;

- Front control arm converted from a six-piece weldment;

- Rear trailing arm converted from an eight-piece weldment.

The ductile iron castings; front fork, front control arm, and rear trailing arm helped to position the commercial zero-turn mower models as best on the market. More specifically, the mowers’ rear suspension features a three-link trailing arm—the first and only of its kind in the industry. Matched with front suspension arm and fork, the result is a smoother ride, more consistent tire contact, and increased hillside stability. It also more reliably withstands rigorous commercial use. Overall, the consistency and replication of the three ductile iron castings are more precise, thereby enhancing fit, function and performance.

- Increased durability and wear performance.

- Eliminated part gaps and warping.

- Streamlined mower assembly through scheduling and labor efficiencies.

- Realized zero warranty claims for the lifetime of the product to date