Case Study

Conversion Transforms 10-Piece Weldment to Single Gray Iron Casting

COLLABORATION WITH OUR CUSTOMERS can lead to reduced costs, quality improvements, and often, better sleep at night.

A recent design project with the world’s largest agricultural equipment manufacturer is a shining example of what working together on gray and ductile iron casting designs can accomplish.

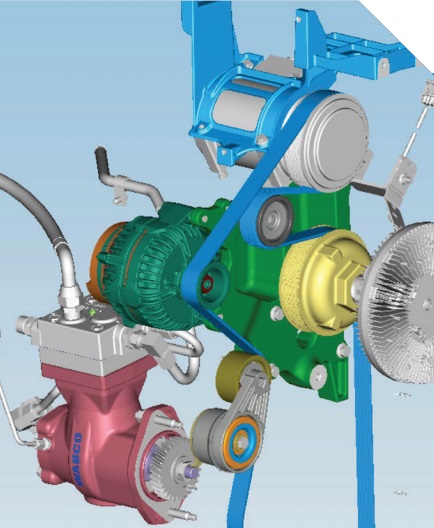

Our customer needed a stronger, lighter alternative to the 66 pound, multi-part weldment used in their equipment. The old model was heavy and awkward to work with. It needed a makeover.

“Basically,” said Plant 5 manager Shelby Applegate, “they asked us to make it better... and we did.”

Waupaca Foundry had the opportunity to do some design modifications that would convert their part from a weldment to a ductile iron casting. Building on a history of collaboration and leadership, Waupaca Foundry worked with the customer to create the perfect part. This is something Tooling Engineer Charles “Robert” Guillaume said could happen at any step of the process, but “it’s important for everyone to be on the same page.”

COLLABORATIVE DESIGN

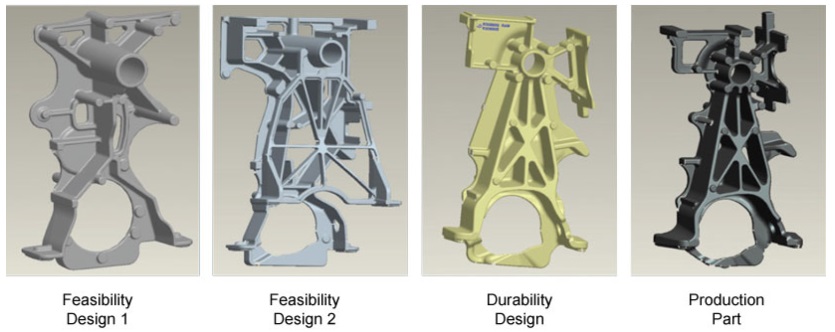

Through innovative design modifications, we were able to reduce the complexity and weight of this part.

By working closely with our customer, we transformed a ten-piece part into a one-piece part. We made it 23 pounds lighter. The redesign simplified tractor assembly for our client and reduced their inventory and administrative costs. Once a highly specialized part, the new design’s higher quality replaced several fabricated and weldment parts, becoming a common component to a number of the customer’s tractor engines.

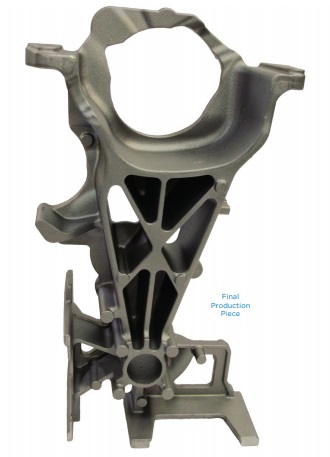

Before

A heavy, complex, multi-part weldment in need of a makeover to become stronger and lighter.

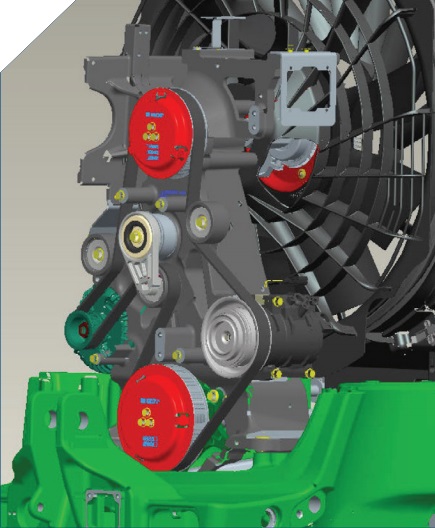

After

The switch from weldment to a single, gray iron casting further established iron castings as viable cost-saving solutions for OEMs.

At Waupaca Foundry, we’ve always known the virtue of collaborating and being willing to tackle tough challenges. Both teamwork and problem-solving are absolutely integral to making the best iron castings in the world.